i-Kabin: what an adventure!

Last June, we were mandated by AESP Green Energy to design and develop the electrical and software portions (embedded and M2M) for the i-Kabin. These cabins will be used to charge cell phones and mobile batteries for villagers in Ivory Coast living without electricity. Our mission was to build eight charging cabins, seven of which being launched in Ivory Coast with a very tight deadline. Talk about a major challenge!

About AESP Green Energy

AESP Green Energy is a corporation that specializes in the development of sustainable energy solutions. Incorporated in 2013, AESP Green Energy is an offshoot of Decoupage AESP Inc., which was, for 13 years, a metal fabrication subcontractor for the Canadian and US markets. During the last five years, Decoupage AESP has developed a range of completely autonomous hybrid streetlamps (solar/aeolian). At the beginning of 2013, the company owners decided to transfer their “know-how” to a new company with an ecological focus.

The Need

After an in-depth market study, AESP Green Energy redirected its development by focusing on the 600 million sub-Saharan inhabitants living “off-grid”, meaning without access to electrical power system infrastructure. Despite efforts made to achieve the electrification of sub-Saharan Africa, the World Bank predicts that the off-grid population will grow to more than 700 million by 2024. The potential market, totaling more than 50 billion dollars and in constant evolution, is ready to be exploited.

After many trips to sub-Saharan Africa, including Nigeria, Ivory Coast, Tanzania, Uganda, Ethiopia and South Africa, AESP Green Energy started focusing its efforts on the research and development of a clean, efficient and cost-effective alternative solution to kerosene-fueled lanterns that represent the main light source for the 600 million individuals living off-grid.

The Solution and Operation

AESP Green Energy developed a “community” approach to provide clean and affordable electrical energy since the i-Kabin, which is patent pending, is a solar charging station installed in the centre of the village and designed to charge mobile batteries (i-Packs). These batteries can be used for residential lighting, to charge mobile phones and to power a wide range of electrical appliances.

The i-Kabin is designed to charge 100 i-Packs weekly, which translates into 100 clients or homes. An Internet connection, possible even in the most remote regions, allows remote communication with the cabins. This function is used for various operational reasons, such as monitoring the equipment’s condition and for mobile transactions, which are already very popular in Africa.

The i-Kabin concept is quite simple; the mobile battery, called an i-Pack, is bought at a reasonable price by a user and can be charged only by an i-Kabin charging station. These 17 amp hr (Ah) i-Packs have two 3W DEL lights and a USB multi-connector and can be used to charge essential devices such as mobile phones. Depending on the consumer’s load demand, the battery will have 50-hour autonomy. Depleted batteries must be taken to a nearby i-Kabin station in order to be charged over an 8-hour period. Each station can charge approximately 100 batteries weekly and the client pays the station’s operator the charging amount, which is equivalent to purchasing kerosene for lighting.

In the entire world, it is sadly still common for people to use kerosene-fueled lamps to light homes. On top of the harmful impact of smoke on the air quality, there is a risk that the nude flame will start a fire. With i-Kabin, residents will be able to enjoy a clean light source that will allow children to do their homework long after the sun has set. i-Kabins will also help local businesses stay open later, thus improving the community’s quality of life as well as local economy. What is more, in Africa, most money transactions are completed through a mobile application via cell phones. Cell phones have become essential to purchase and sell goods and services and are crucial to the country’s economic development. It was obvious to AESP Green Energy that a cell phone charging solution was necessary. Finally, i-Kabins help create microbusinesses in targeted villages. In fact, cabin operators buy and resell charging credits, which helps generate an income. This helps stimulate local economy.

Currently, seven prototype units have been deployed and are being used in Ivory Coast. AESP Green Energy implemented a realistic growth plan that includes deploying - as of the second quarter of 2015 (Q2) - 2,100 units for the first year, 3,200 units for the following year, followed by 300 i-Kabins each month for the 36 subsequent months. Finally, since the beginning of 2015, AESP Green Energy has been gathering many statistics on the use of i-Kabins in order to secure the financing to pursue the program. During the first three months, more than 2,000 cell phones and batteries have been charged. This number clearly demonstrates the need and interest for i-Kabins in sub-Saharan Africa.

The Electronic Design

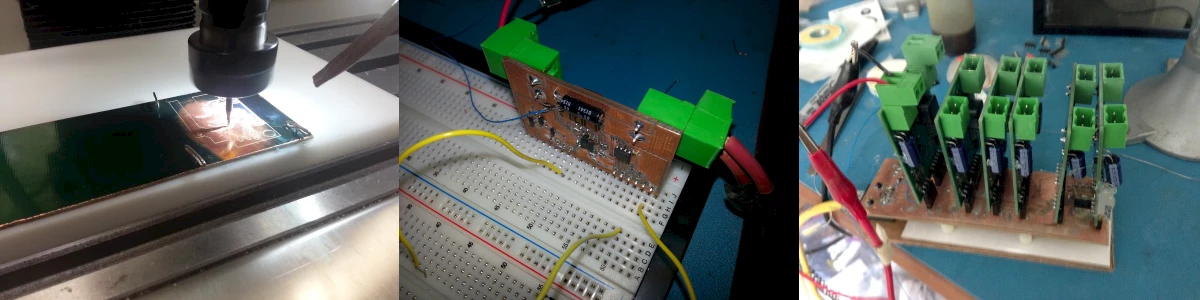

Our mission was to design, develop and build the i-Kabin’s electronic/electric aspect and software. To do so, we designed the printed circuit board (PCB) for the battery and cell phone chargers using CadSoft’s Eagle software. We also designed a circuit to collect data and communicate with the chargers via an I2C interface.

Given the particularly tight deadline and given the fact that the “time to market” was final, we built the circuits for the eight cabins manually. To do so, we first built prototype chips using a CNC machine and put the electronic components into place. With an oscilloscope, logic analyzer and manual multimeter, we conducted all the required tests to make sure that the concept was working before producing the circuits for the prototypes.

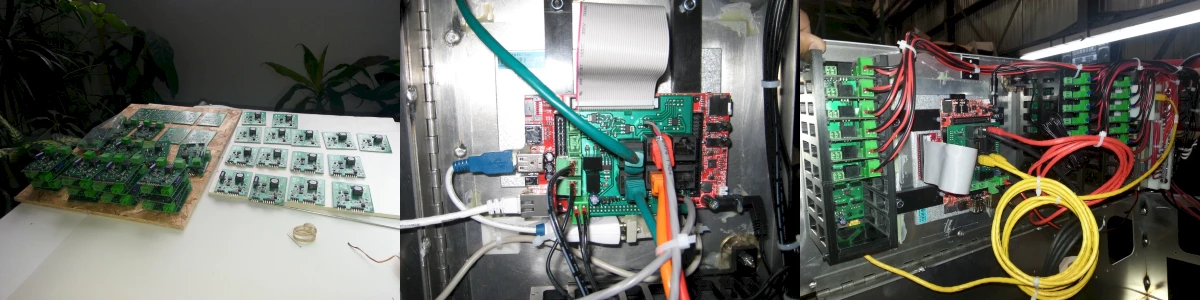

Once the concept’s proof passed the test, we had the printed circuits (chips only) built by Sunstone. Due to time constraint, we manually assembled the components on the chips. We’re talking about more than 200 circuits assembled in less than a month, using soldering irons, a heating plate, our templates and our own hands. We favoured existing components, when available, but were faced with various challenges that required us to be creative and original.

After testing everything, we produced our very first i-Kabin. This cabin is now displayed in AESP Green Energy’s St-Eustache office of to be shown to investors. This first cabin was useful to us in many ways. Firstly, we were able to test the user experience as a whole. Secondly, we used this cabin to pursue tests on battery charging. Finally, we were able to test our communication layer on the 3G network to make sure that everything was functional for remote maintenance and to gather the necessary metrics and parameters. Recording and acquiring metrics via a cellular network (M2M) is essential in understanding how people use the cabin. For example, it is possible for us to know how many charges are done every day. We also get a general view of the health of the cabins, which send a “heartbeat” to our servers to confirm that the system is functional.

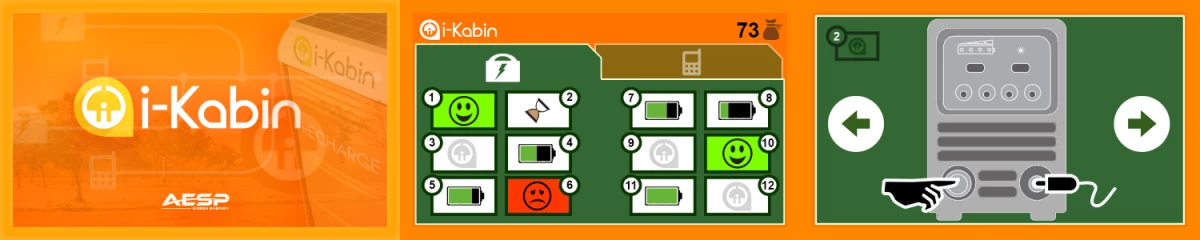

The Operator Interface: a Simple User Experience!

Given the fact that we were dealing with a culture very different from ours, we did some research relating to user experience. To this end, we conducted interviews with Ivorians living in Quebec in order to adequately understand the Ivorian reality. This research guided us in developing a user interface that is both easy to use and adapted to this culture, regardless of the operator’s education or literacy level.

Embedded and M2M Development

For the embedded development, we chose Olimex’s OlinuXino A20 as our microcontroller (or mini-computer to be more precise). This little jewel contains an ARM Cortex-A7 processor with a 1GB memory, which can easily run Linux. To ensure proper communication between cabins, we chose the Janus T2 Terminus M2M modem. Finally, Solantro’s DC-PODX was chosen to manage the energy input coming from the solar panels. To integrate everything, we built an expansion board that could be grafted onto the OlinuXino microcontroller in order to connect everything together.

To secure communication between the components, we used I2C and RS232 interfaces. For example, Solantro’s controller allows us to manage and monitor energy input and output through a serial port, while the I2C interface gives us a reading of the energy distributed by the chargers.

To develop the operator’s software, we used various technologies and languages such as Python, JavaScript and Bash scripts. Python is the language of choice and is well known in the world of embedded technologies. It helped us to quickly develop the operator’s application using Flask. As mentioned earlier, the “time to market” was crucial so we chose to reuse existing tools under Linux. We developed a communication layer using Bash scripts, which allowed us to put essential functions in place quickly and build robust and proven technologies.

The Server Side

We also developed an administrator portal accessible on our servers. We selected the Django platform, which we paired with MySQL, Bootstrap and jQuery.

The administrator portal allows us to easily monitor what is going on in the entire system and in each cabin individually. We have a dashboard that displays information and metrics in real-time. At a glance, we can quickly identify a problem and react if necessary, thanks to the solid communication layer I described earlier. The portal displays the credit balance for each cabin, the list of transactions, the solar panels’ performance, the batteries’ charging profile, the cabins’ “heartbeats” as well as a large array of information to help us detect problems. We even have a weather section to help us compare the solar panels’ performance with the temperature in Ivory Coast!

Deployment in Ivory Coast

Once the seven i-Kabins built for Ivory Coast were finalized and duly tested, we wrapped them and sent them to the city of Abidjan. It was then our turn to take off to Ivory Coast to complete the installation. We assembled the cabins in a warehouse in Abidjan and then deployed them in different villages. Access to these villages – also known as communes – can be difficult and we had to travel on pretty interesting roads while being extra careful not to damage the cabins on our way.

The targeted villages were Moussadougou, Ledoux-Lagazé, Gango 1, Kpotè and Boko. We installed three cabins in Moussadougou since it is relatively bigger with 36,000 inhabitants. In Quebec, I suppose we would call it a small city. In this first phase, each cabin can charge 75 batteries.

The villagers were waiting for us anxiously! To them, the i-Kabin is going to change their lives. In fact, the goal of the first phase was to do tests and assess, on site, the chances of success and the population’s interest in this big and beautiful initiative. The seven i-Kabins that we deployed are clearly not sufficient to meet the demand. However, it is now clear to us that we have to take the next step. Thousands of i-Kabins will have to be built in order to serve the sub-Saharan region of Africa. Ivory Coast was just the beginning. In the end, we made these villagers very happy. It is so rewarding to know that we are making a difference!