Personal 3D printing: so “last year”?

Today, you only ever hear about it in tech news, and even then… As the owner of a 3D printer, I’d like to share my impressions on the craze, the ensuing disappointment, and the current situation as I see it.

The flood tide

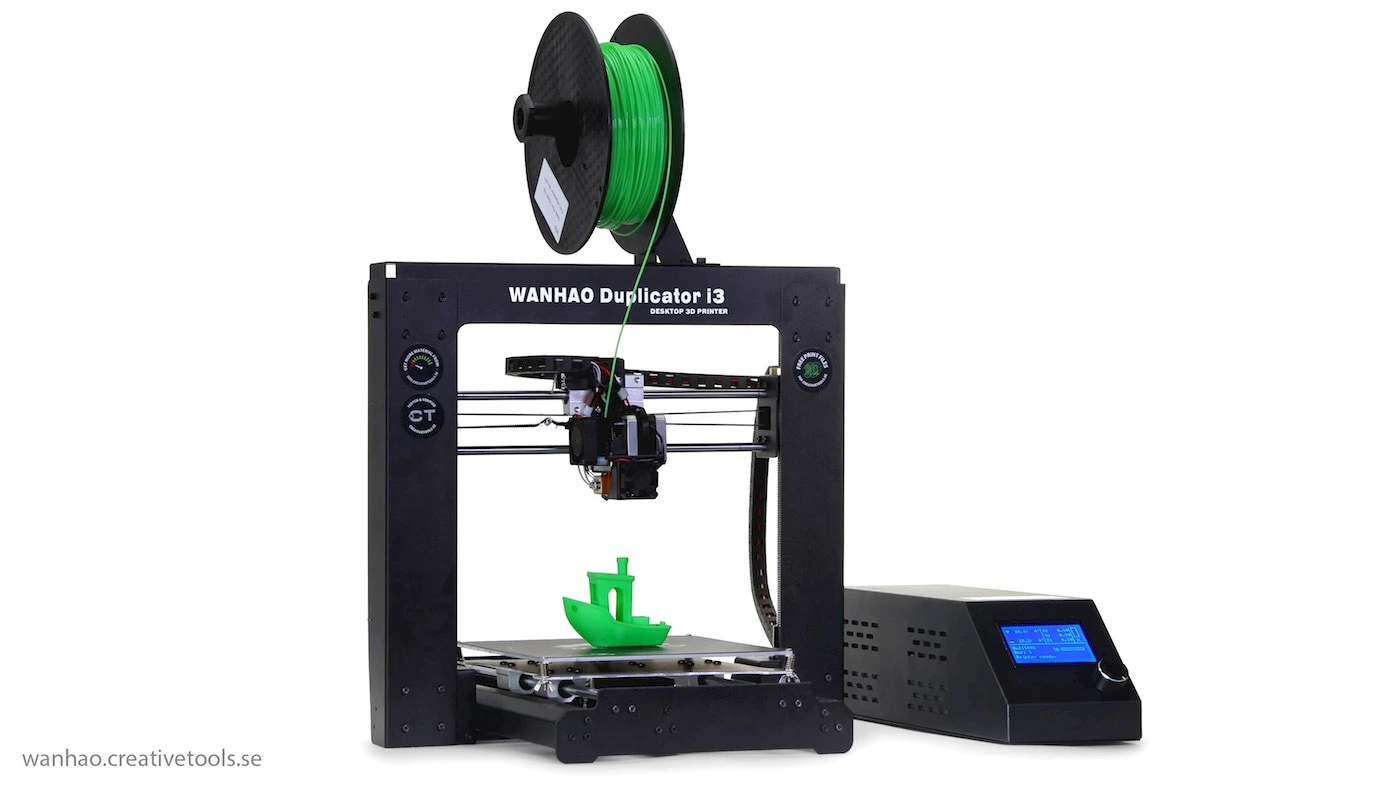

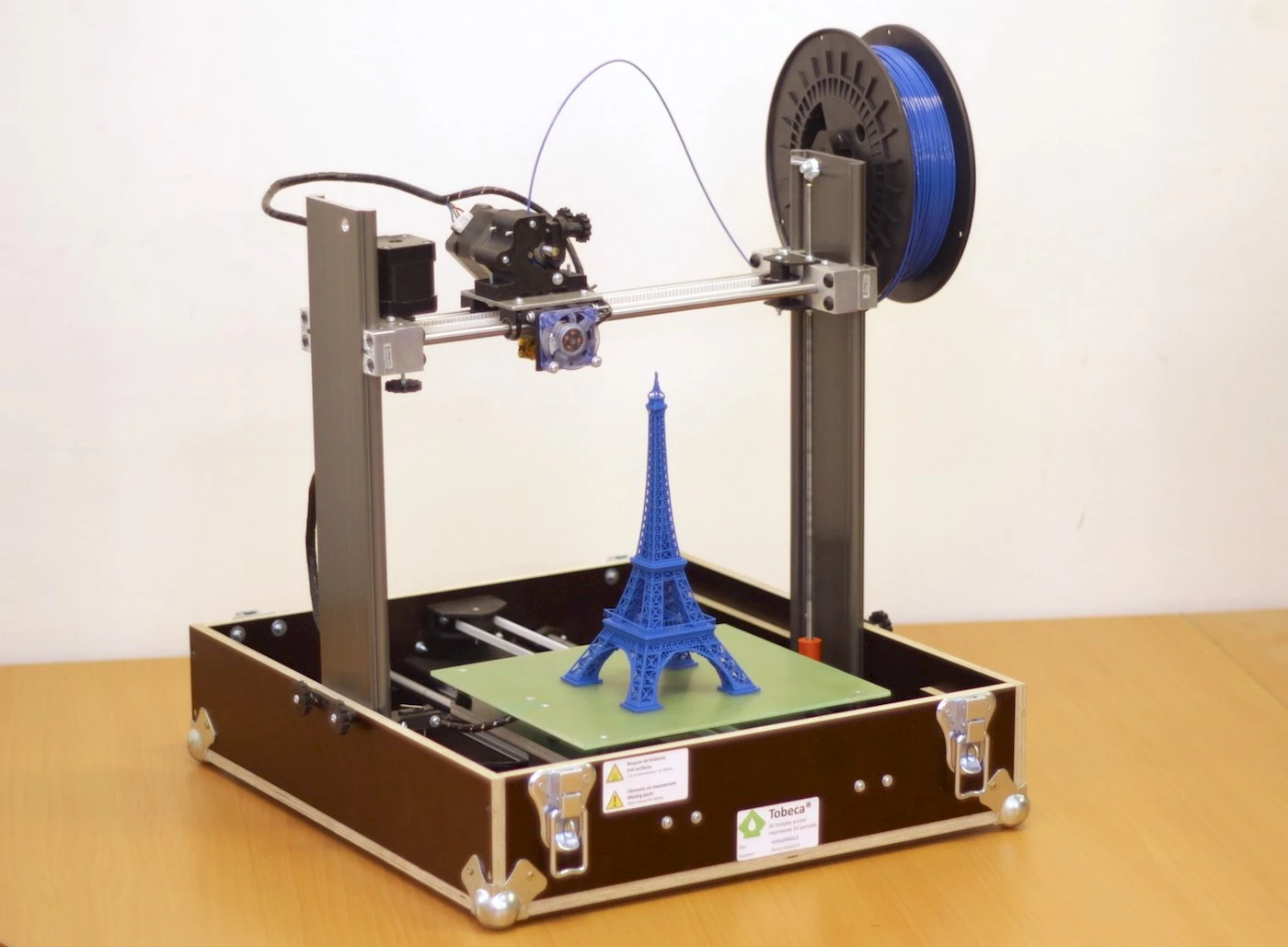

Before the tide hit its peak, 3D printers were rare, costly and difficult to build. They tended to be industrial machines or toys built by tinkerers and do-it-yourselfers. But even as the tide was rising, the DIY community had managed to build cheaper machines costing around 400 to 600 dollars. Smaller companies started selling fully-assembled machines requiring minimal maintenance.

The high watermark: promises of revolution

The tide hit its peak when the average consumer was able to afford a 3D printer guaranteed to be problem-free. That’s when journalists started talking about a revolution for consumers, who could now print instead of buying. By that time, I had already been the proud owner of a 3D printer for several months. Several people offered me good coin to print stuff for them, and kept coming back. The 3D-printed product market was at its peak, as few people were interested in spending $2,000 on a complete printing solution, and even less in building their own.

The ebb tide

The tide receded as quickly as it had surged. People started selling their printing kits, sometimes still in the box. My list of clients dried up, and people forgot about the very existence of the technology. In my opinion, there were two reasons for this sea change:

The technique is quite complicated. Even today, 3D printing is a long and complex process. Before printing, you first have to create a model, then adapt it for printing, and finally generate the code needed for machine reading. Then, you still have to calibrate the printer, fire up the printer, wait hours for your model to be completed — an exercise in patience — and finally finish the model by removing burrs and cleaning up other imperfections.

— The availability of 3D printing does not create a need to use it. The innovation is there for the taking, but most people have no idea what to do with it. The early hype ended in an anticlimax.

The good news is that the non-industrial 3D printing market is still alive, thanks to the enthusiasm of a few devotees. And the technological advances made possible by the craze have improved the machines immensely. The tide peaked too soon, when the technology over-promised and the promises under-delivered, which led to disillusionment within the general public.

In closing: the industrial market was the big winner of the 3D printing craze. The mechanical parts industry and the very design of mechanical parts was transformed by the simplicity of prototyping with 3D printing. Whether it be scale models, injection molding or small-run parts production, everything is now faster and cheaper.